自动插件机 卧式联体跳线插件JVA

全自动卧式跳线插件机

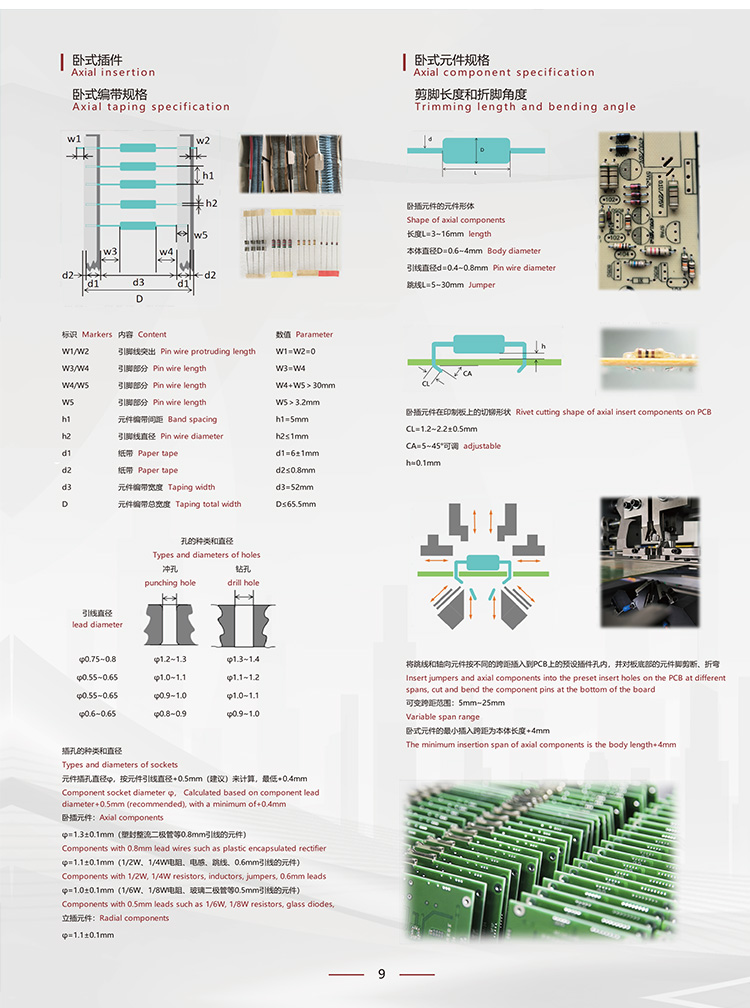

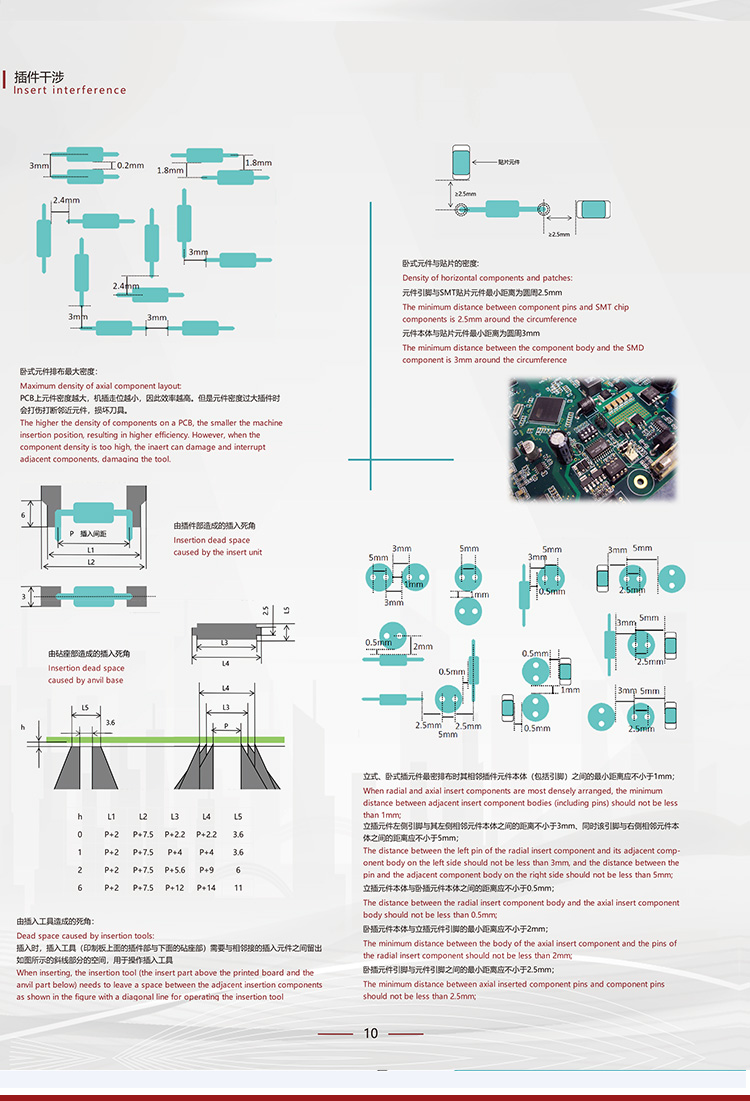

元件种类:标准0.6mm线脚,直径0.4-0.8mm(可选配)镀锡铜钱跨距;引线跨距5mm-30mm;电容、晶体管、二极管、电阻、熔断丝等编带封装料及跳线。

型号 | Model | JVA(跳线机) |

理论速度 | Theoretical speed | 0.16秒/点 0.16sec/pcs |

插入方向 | Insertion angle | 平行0°,90°,180°,270° Parallel |

元件种类 | Components style | 跳线 jumper |

元件规格 | Components specifications | 引线直径:0.4~0.8mm Lead diameter |

引线跨距 | Lead span | 专插入跳线5~30mm Specially inserted jumper |

元件引线剪角长度 | Component lead trimming length | 1.2~2.2mm(可调) Adjustable |

元件引线弯角角度 | Component lead bending angle | 5-45°(可调) Adjustable |

基板尺寸 | Substrate size | 50*50mm~330*280mm |

基板厚度 | Substrate thickness | 0.79~2.36mm (标准:1.6mm) 0.79-2.36mm(Standard: 1.6mm) |

线路板输送方式 | Circuit board transportation mode | 全自动:左→右(标准)或右→左(选配) Fully automatic: left right (standard) or right left (optional) |

基板传送高度 | Substrate conveying height | 900±20mm |

基板传送速度 | Substrate transfer speed | 3 sec/pcs |

PCB上下元件可通过高度 | Components pass through height on PCB | 上12mm/下8mm 12mm above/8mm below |

驱动系统 | Driving system | AC伺服,AC马达 AC servo, AC motors |

孔位校正方式 | Hole position offset method | CCD影像视觉系统,多点MARK视觉校正 CCD Image visual systems, multi-point MARK visual correction |

底座驱动方式 | Base drive mode | 伺服电机 Servo motor |

供料器方式 | Base drive mode | 跳线站 Jumper station |

编程方式 | Programming method | 离线/在线(快速扫描编程功能) Offline/Online (Quick scan programming function) |

数据输入方式 | Data input methods | USB接口输入(EXCEL文档格式) USB input (EXCEL document-format) |

Badmarks识别 | Identification of defective PCB board | 具有不良PCB板自动识别功能 Automatic recognition function for defective PCB boards |

控制系统 | Control system | Windows操作系统中英文界面、视窗平台、液晶显示 |

MES系统 | MES system | 无 Without this feature |

使用电源/功率 | Power requirement | 220V,AC(单相)50/60HZ ,1.5KW Single phase |

使用气压/用气量 | Use air pressure/gas | 0.6MPA/0.3立方米/分钟 0.6 mpa / 0.3 m³/ min |

设备尺寸 | Main machine size | L1800mm×W1500mm×H1810mm |

机器重量 | Machine weight | 约1300KG Approximately 1300kg |